Intended Market

By in large, amplifiers are massive heavy objects that require setup and breakdown before and after the show. In many cases this includes a multitude of guitar pedals and wires connecting each of them. An amplifier that utilizes these high customizability digital softwares doesn’t exist in the mass market.

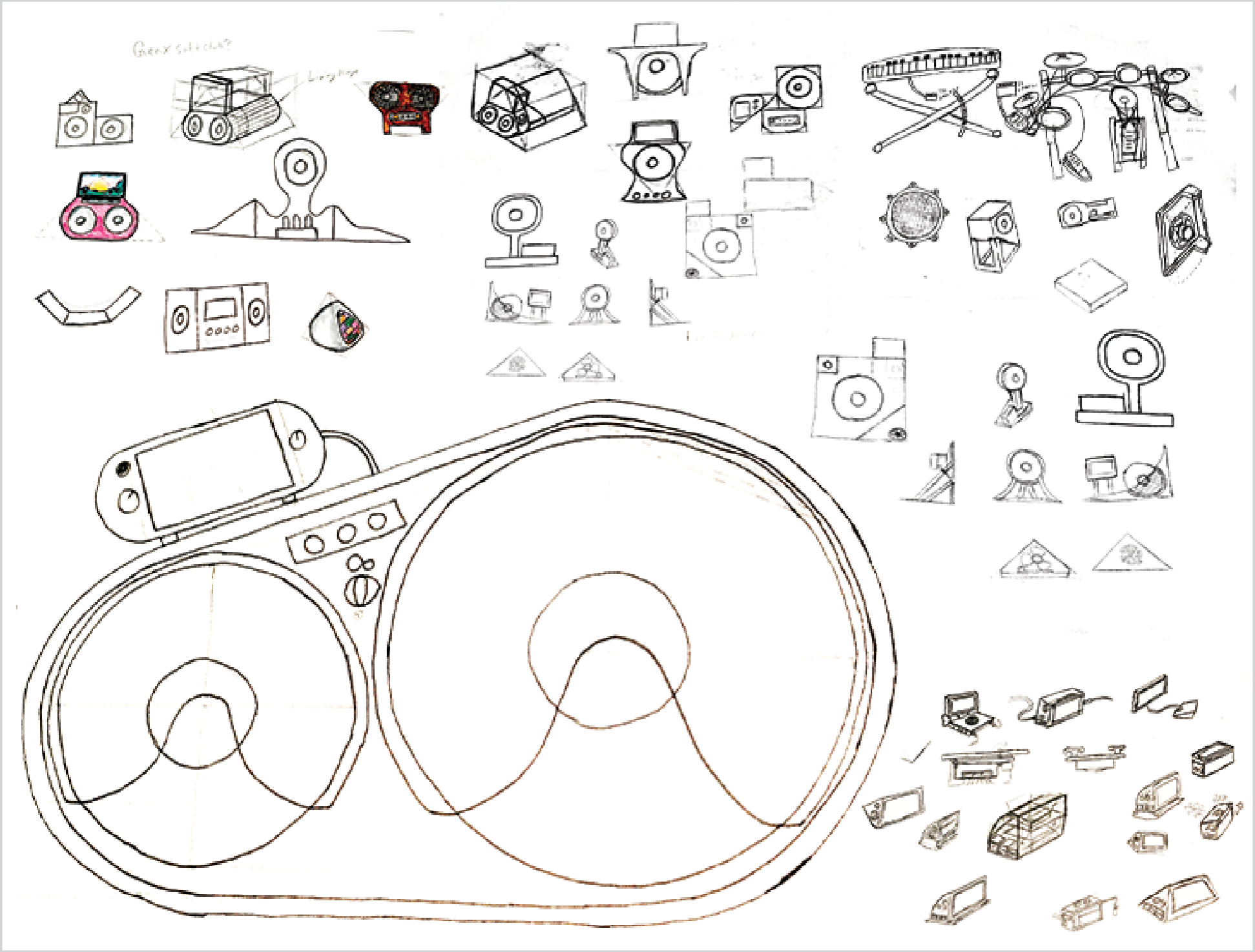

Ideation and concept starts with paper sketches

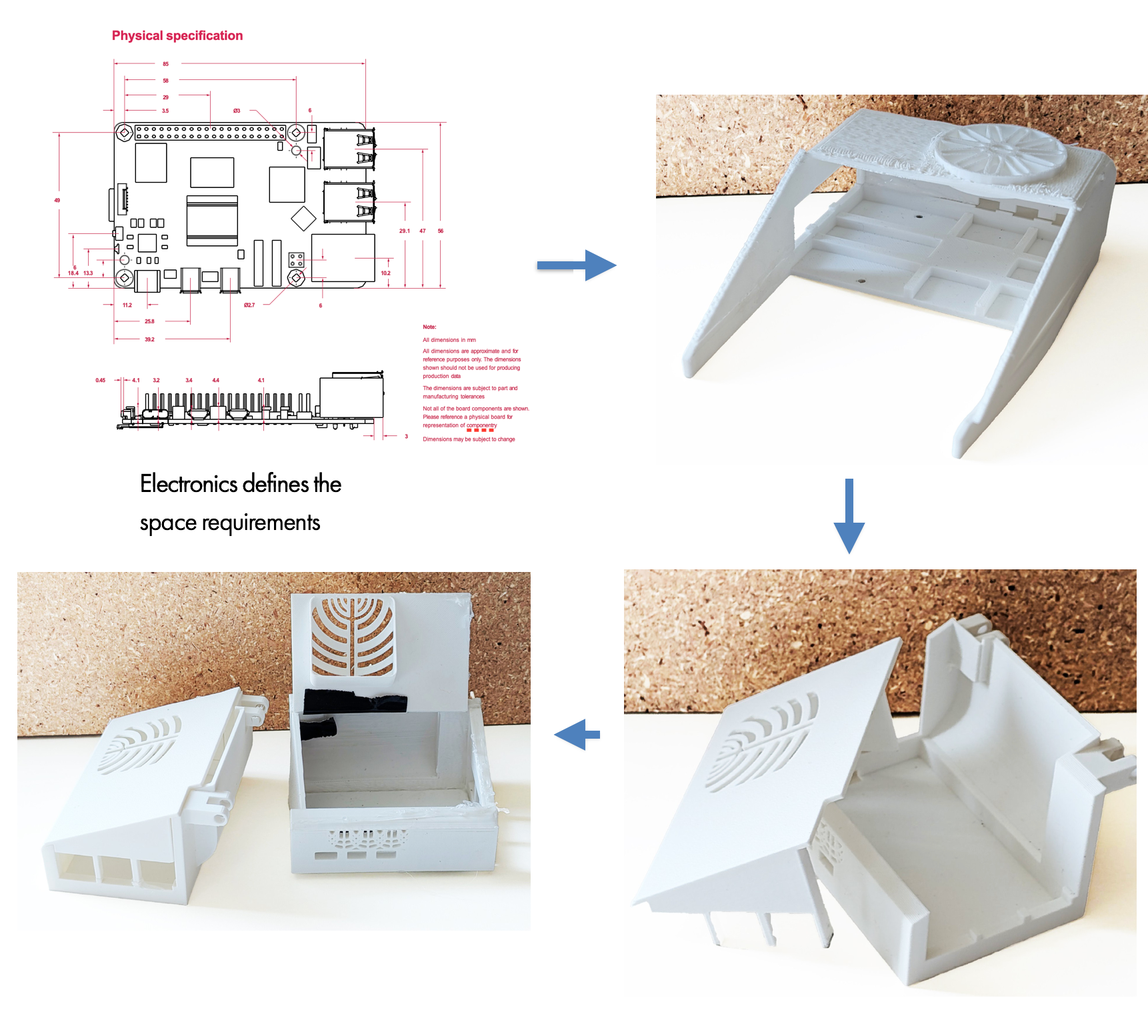

My focus during during concept development: shape and assembly methods Influenced by explorations of forms which begun at 90’s style aesthetics. These designs were centered around the technological requirements of this project. The decision to use 1 guitar and 1 digital speaker in order to produce both the gritty tone that typically comes out of guitar speakers, and the clarity that comes from digital speakers.